IoT Monitoring

Ryobi-G’s fully automated IoT monitoring system delivers live insights underground no manual readings required. With seamless sensor integration and instant data access, we help you monitor safely, respond faster, and make smarter decisions across complex infrastructure projects.

As urbanization accelerates and infrastructure ages amid climate challenges, real-time, accurate monitoring is essential. Traditional manual methods can’t keep up.

Ryobi-G offers a fully IoT-powered monitoring system that delivers real-time visibility, automation, and intelligent data for geotechnical and structural projects in complex environments.

Our platform integrates a wide range of sensors vibrating wire piezometers, inclinometers, strain gauges, fiber optics, extensometers, and robotic total stations streaming live data to a secure cloud dashboard. Engineers can monitor conditions remotely 24/7, receive automated alerts, analyze trends, and generate instant reports, improving safety and response times.

Using wireless transmission (LoRa, NB-IoT, or 4G), site visits are minimized. Unlike isolated or manual systems, Ryobi-G provides a scalable, plug-and-play IoT ecosystem from sensor setup to dashboard customization making it easy to manage projects of any size.

With a proven track record across Southeast Asia, Ryobi-G empowers teams to make faster, safer, and smarter decisions from underground to the cloud.

-

URBAN & INFRASTRUCTURE MONITORING

URBAN CONSTRUCTION MONITORING WITH IOT INTEGRATION

This dynamic urban environment showcases real-time connectivity through strategically placed loT points-highlighted across machinery, vehicles, buildings, and infrastructure.

From the bustling construction pit to the surrounding streets and rail systems, every element is connected, monitored, and optimized for safety, efficiency, and sustainability.

-

STRUCTURAL & ENVIRONMENTAL SENSING

PRECISION MONITORING FOR SMARTER CITIES

This cityscape features an loT-powered surveying system.

A smart instrument connects wirelessly to multiple sensors on buildings and the ground including the Ryobi G device, capturing precise measurements for structurallhealth, alignment, and urban developmen efficiency, and sustainability. -

TRANSPORTATION & PUBLIC SAFETY

IOT MONITORING AT TRANSIT HUBS

This train station platform features an loT-enabled monitoring system.

Our scanning device actively scans the area connecting to multiple points. across the platform. The system enables real-time data collection for crowd flow, platform activity, and infrastructure conditions. Supporting safer, more efficient transit operations through intelligent monitoring.

-

GEOTECHNICAL & ENVIRONMENTAL MONITORING

SUBSURFACE MONITORING WITH IOT SENSORS

A sensor is embedded below ground, connected to a Ryobi G device at the surface.

This setup enables continuous monitoring of subsurface conditions such as fluid levels or soil stability. Data is transmitted in real time, supporting proactive decision-making in construction, environmental, and geotechnical applications. efficient transit operations through intelligent monitoring.

-

COMMUNITY IMPACT MONITORING

CONSTRUCTION ACTIVITY DETECTION IN RESIDENTIAL ZONES

A Ryobi-G device, powered by a solar panel, monitors construction activity near residential buildings. The system detects environmental and structural changes such as noise, vibration, and movement, triggered by nearby worksites with integrated signal-based detection and real-time alerts. It helps ensure safety, compliance, and minimal disruption to the community

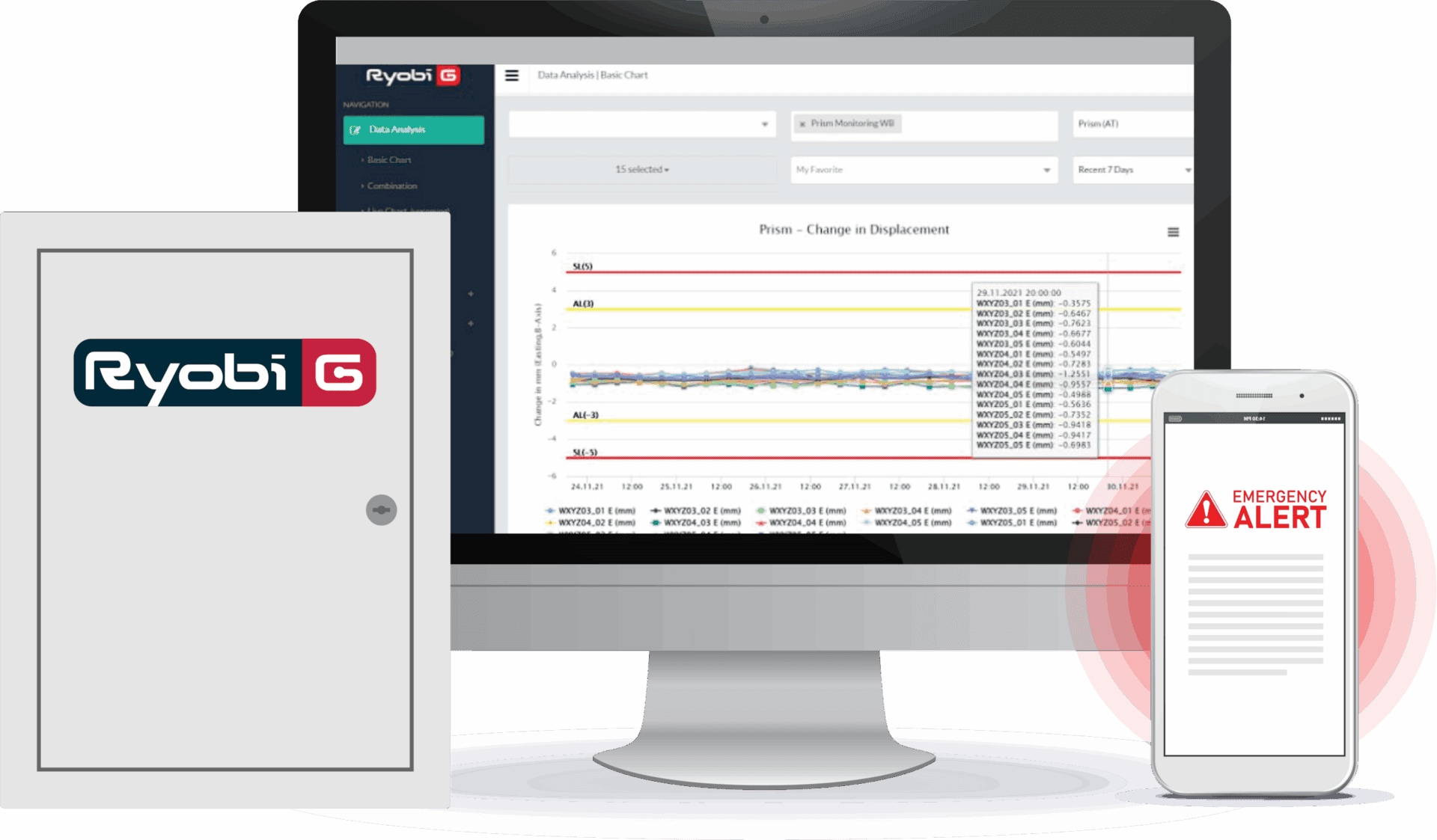

Access live, high-frequency data anytime, anywhere

Real Time Data Visualization: Live sensor data visualized via secure dashboards.

Instant Alerts: Receive real-time SMS/email notifications for threshold breaches.

Historical Data Trends:Access past data to identify trends, analyze performance, and support engineering decisions.

Multi-Sensor Integration: Supports industry-standard loggers and sensors (e.g., piezometers, inclinometers, tiltmeters, extensometers).

How It Works

Sensor Installation

We start by installing various sensors on-site, depending on the monitoring requirements.

Data Logging & Transmission

Sensors connect to specialized loggers that collect readings at set intervals and transmit data wirelessly via 4G and NB-IoT communication network

Centralized Processing & Backup

Data is sent to a central server for processing and analysis, with automatic backup to a secondary server for data integrity and redundancy.

Visualization, Alerts & Access

Processed data is visualized via the WIRS platform, shared through push facilities, monitored by a health check system, and critical alerts are sent instantly to users — while raw data is archived securely for future use.

Industries We Serve

Tunneling & Shaft Monitoring

Railway & MRT Infrastructure

Airports & Aviation Zones

Urban Development & structural

Slope & Embankment Stability

Automated, Scalable & Wireless

Our systems use LoRa, NB-IoT, or 4G to transmit data in real time. Matching your project, from compact sites to large infrastructure networks

Completed IoT Monitoring Solutions

We provide end-to-end support—from sensor setup to dashboards—powered by civil engineers who understand site needs and in-house teams who build our proprietary monitoring systems. This ensures seamless execution and reliable, real-world performance.

Actionable Insights, Instantly

Our secure cloud dashboard turns raw data into visuals, trends, and smart alerts—enabling faster, safer, and more informed decisions.

Featured Projects

Cross Island Line (CRL) – Urban Tunnel Monitoring

Urban Geotechnical & Structural Monitoring

We’ve supported over 40 civil contracts across major infrastructure projects, including 7 of them from the Cross Island Line. Installed 1,000+ instruments near live MRT lines and urban zones, using ATS, piezometers, tiltmeters, and IoT dashboards to monitor movement, pore pressure, and ground conditions.).