High Resolution Imaging

Ryobi-G is constantly developing and upgrading our high-resolution imaging systems to keep pace with the challenges faced in the ever-growing infrastructure and maintenance requirements.

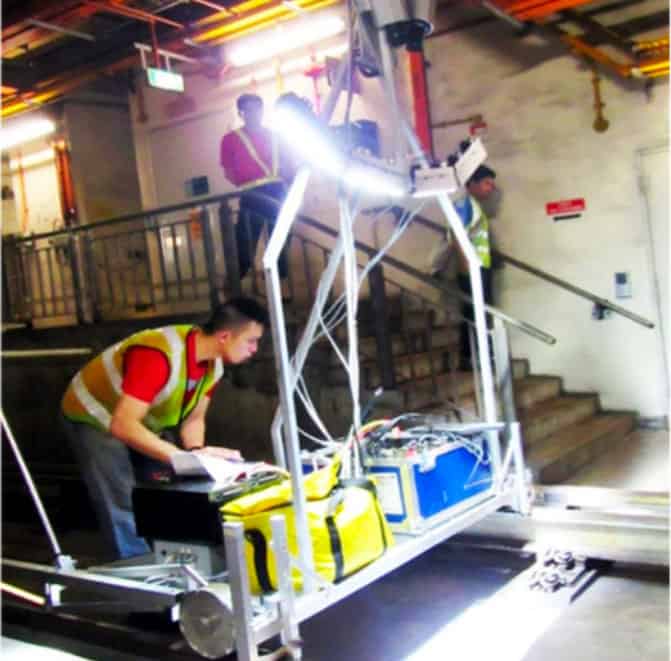

ADVANCED MODULAR SYSTEM DESIGN

Today, there are many discussions and explorations on how structural cracks can be detected and documented automatically. In Singapore, these inspections are usually carried out by a Professional Engineer (PE) carrying out visual inspections on the concrete structures and manually documenting the cracks sighted. However, these cracks documentations are still limited to the eyesight and judgement of the PE, especially with fine cracks on the ceiling of tunnels.

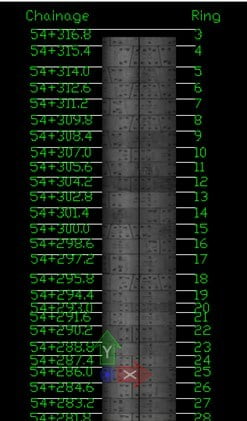

GEO-REFERENCED DOCUMENTATION

Having captured the full surface of the tunnel in high resolution images, there is almost no limitation on inspection of cracks or defective fittings along the tunnel at the comfort at desk.

The high resolution images are tagged with chainage by the positioning system in realtime, this allows engineers the possibility and ease to identify the location of defects detected such as cracks from the images at the comfort of their desk instead of the warm and humid tunnel conditions.

COMBINATION OF HIGH PERFORMANCE LINE CAMERAS AND LIGHTINGS

The special lighting allows the line cameras to capture sharp and clear images in the kinematic mode. The images are tagged with chainage by the positioning system in realtime, this allows engineers the possibility to locate and detect the cracks from the images at the comfort of their desk instead of the hot and humid tunnel conditions.

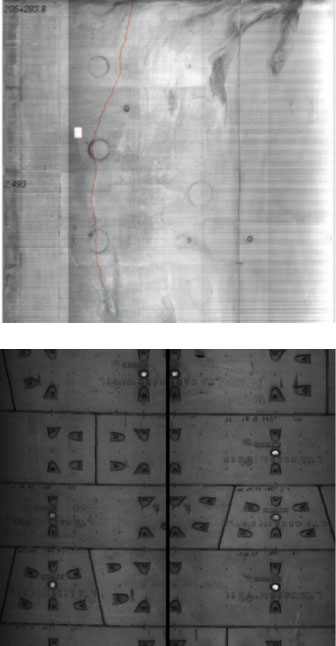

The captured images comes with a scale for the engineers to determine cracks dimension as narrow as 0.3mm.

CLASSIFICATION OF CRACKS

The special lighting provides parallel beam of high lumen light source allowing the line cameras to capture sharp and clear images in the kinematic mode. The captured images comes with a calibrated scale for the engineers to determine cracks dimension as narrow as 0.3mm. Engineers can then classify the cracks which needs to be repaired or monitored by highlighting with different colours for respective cracks

MAXIMUM EFFECTIVENESS

Ryobi-G is derived at constantly developing and upgrading the high resolution imaging system to keep pace with the challenges that engineers faced in the ever growing infrastructure and maintenance requirements in Singapore and the region. Should you be interested in the above services, kindly contact us.